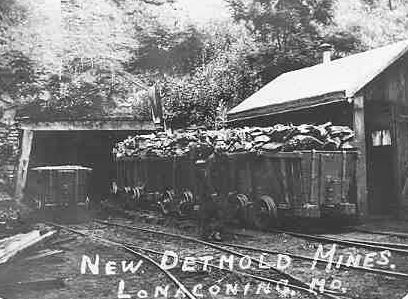

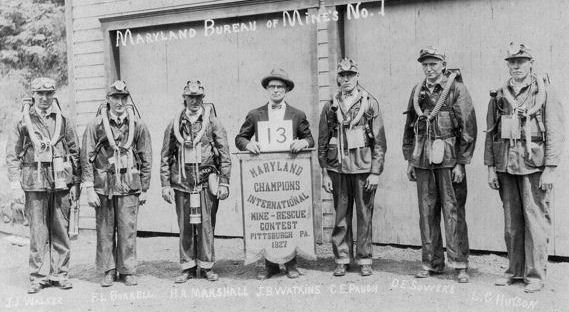

MARYLAND MINES

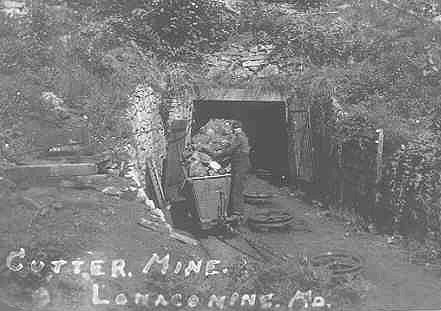

Moscow Mining Co. Lonaconing, MD

Coal Mine - Reynolds, Maryland

George's Creek Coal and Iron Company, a Baltimore and London syndicate, purchased 11,000 acres of land along George's Creek in western Allegany County, Maryland. The Lonaconing iron furnace built in 1837 was the first in the United States to successfully use bituminous coal and coke, rather than charcoal, in making pig iron. The furnace produced pig iron from 1839 until 1855. By then the mining of coal had assumed a much more important industrial role and the George's Creek Coal and Iron Company, which already owned thousands of acres of land along with the mineral rights, turned to coal mining as its sole interest. Numerous other coal companies were formed and mines were opened on all hillsides.

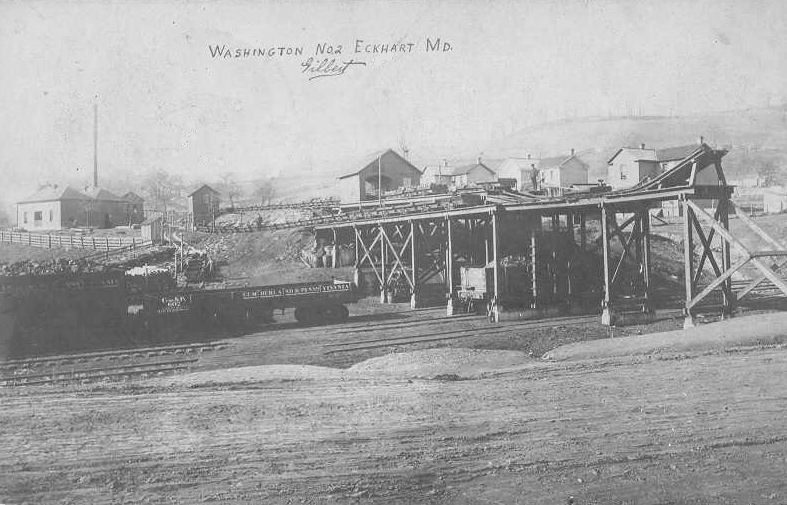

The Maryland Mining Company was a iron and coal mining company operating in Eckhart, Allegany County, Maryland. The Eckhart mines location up Braddock Run were among the first bituminous coal mines developed in the area, together with a few others along Georges Creek. The Eckhart operation was owned by the Maryland Mining Co. Meanwhile, at Mount Savage a little to the northwest, the first pig iron was smelted by the Maryland & New York Coal and Iron Co.

Coal was originally mined here early when the “Big Vein” was opened in 1820. The coal was orginally transported by flatboats placed together on the headwaters of the Potomac. As part of their operations, the Potomac Wharf Branch was built from Will's Creek, west of Cumberland, by the Maryland Mining Company between 1846 and 1850, as an extension to their Eckhart Branch Railroad. The Cumberland Coal & Iron Company, chartered in 1850, purchased the Maryland Mining Company's mines and railroad in April 1852, including the village of Eckhart.

With the arrival of the B&O in Cumberland in 1842, local interests began lobbying for the construction of branch lines leading to the coal mines at Eckhart Mines, and the iron furnaces at Mount Savage. B&O didn't want to invest into branches for political as well as financial reasons. Eventually the Maryland & New York Coal & Iron Co. chartered and built its own Cumberland & Pennsylvania RR with the purpose of connecting with, and hopefully later selling out to, the B&O near the Narrows.

The Consolidation Coal Company was established in 1864 and headquartered in the city of Cumberland, Maryland for the first 85 years (1864-1945) where the company became the largest bituminous coal company in the eastern United States.

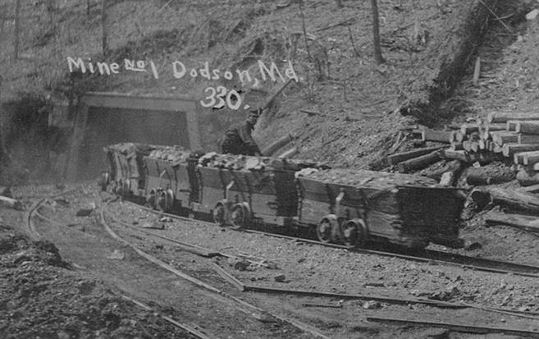

The company's origin began in the early 19th century when a 14-foot (4.3 m) thick seam of bituminous coal referred to historically as "The Big Vein" was discovered in the Georges Creek Valley of Western Maryland. This coal region became famous during the industrial age for its clean-burning low sulfur content that made it ideal for powering ocean steamers, river boats, locomotives, and steam mills, and machines shops. However, coal production did not become important until the Baltimore and Ohio Railroad reached Cumberland in 1842. In 1850, the opening of the Chesapeake and Ohio Canal from Cumberland to Washington, D.C. provided another route for coal shipments. Over 21 million short tons of coal were transported on the canal before it closed in 1923. By 1850, almost 30 coal companies were mining the Georges Creek Valley, producing over 60 million tons of coal between 1854 to 1891. The Consolidated Coal Company was formed as a consolidation of the many coal mine and railroad companies of Western Maryland founded during the rush years. The Cumberland and Pennsylvania Railroad was owned by the Consolidation Coal Company.

Western Maryland's coal production rose about 1 million short tons in 1865, exceeded 4 million short tons by the turn of the century, and reached an all time high of about 6 million short tons in 1907. A small amount of the coal production in the early 1900s was premium smithing coal (as in blacksmith) that was specially processed and delivered in boxcars to customers throughout the United States and Canada.

Sharp declines in coal demand after 1920, reflecting downturns in the economy, recurrent labor problems and the extensive replacement of coal by petroleum, led to further consolidations and mergers in the coal industry. In 1945, Consolidated Coal Company merged with the Pittsburgh Coal Company, and the corporate headquarters was moved from Cumberland to Pittsburgh.

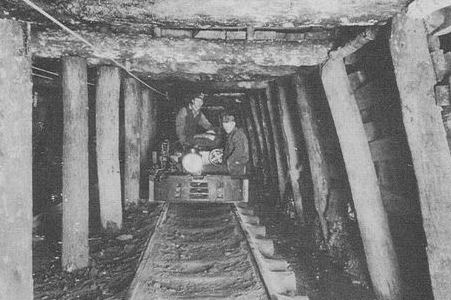

The Hoffman Drainage tunnel was an engineering triumph of its age. Built in the period 1903 through 1906, it was hand-driven through solid rock for 2 miles to provide an outlet for water that was flooding the coal mines. The water had proven to be too much for the steam pumps, and coal production was stagnating. After an engineering survey of the turrel project by the Consolidation Coal Company, a contract was let to Mr. Phillip Jenkins, Sr. of Wales. Work was begun from both ends in November 1903 by Jenkins’ four sons, William, Edward, James, and Phillip, Jr.

The tunnel was punched through on Saturday, July 21, 1906 at 9 pm. It was found to be off by less than three inches. The Frostburg Mining Journal of September 15, 1906, proclaimed, “The Great Work Complete.” Inside the mines, the pumps were silenced, and gravity took over to lower the water level. It is estimated that 9,000,000 gallons of water were drained in 24 hours.

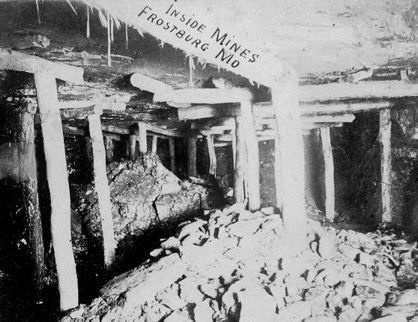

Coal miners - Frostburg, MD

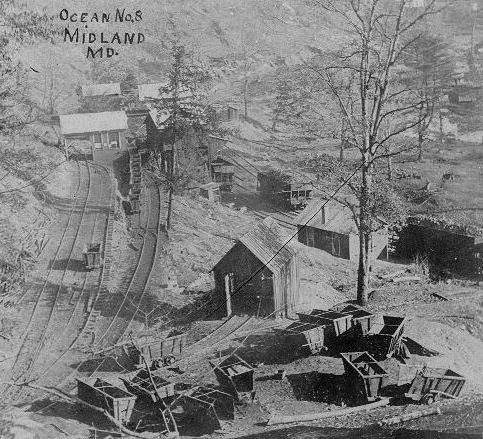

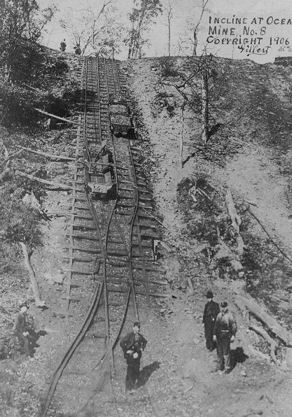

Ocean No.8 Coal Mine - Midland, MD

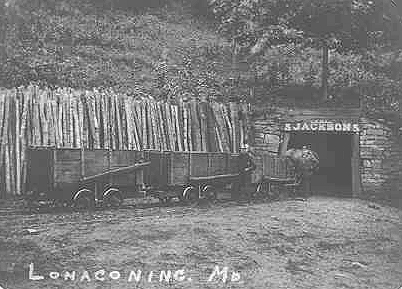

Jackson Mine - Lonaconing, MD

Ocean No.8 Coal Mine - Midland, MD

Hoffman Mine - Frostburg, MD

Georges Creek Coal Company's Big Vein Sonny Mine - Lonaconing, MD

Koontz Mine - Lonaconing, MD

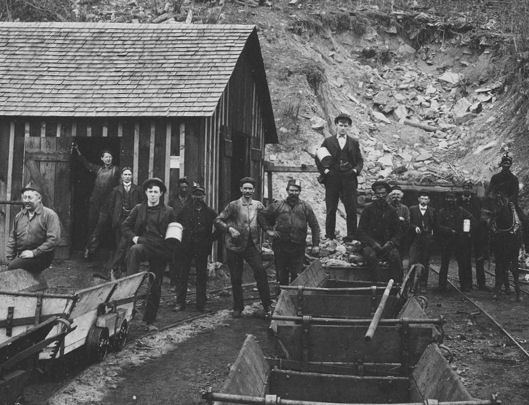

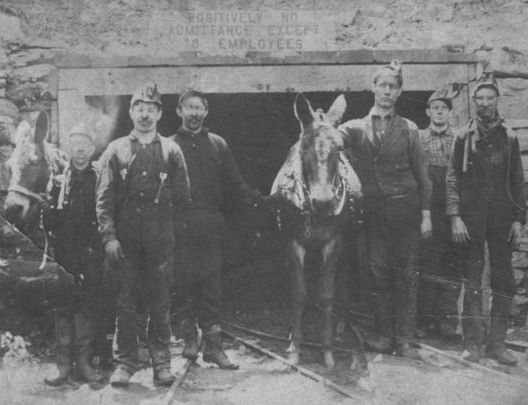

Maryland Coal Miners

Coal Miners - Mt. Savage, Allegany County, MD

Coal Miners - Mt. Savage, Allegany County, MD

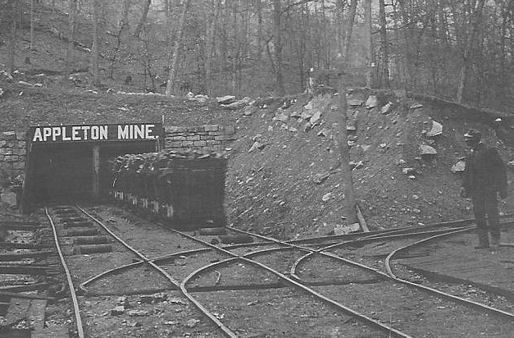

Appleton Mine - Lanaconing, MD

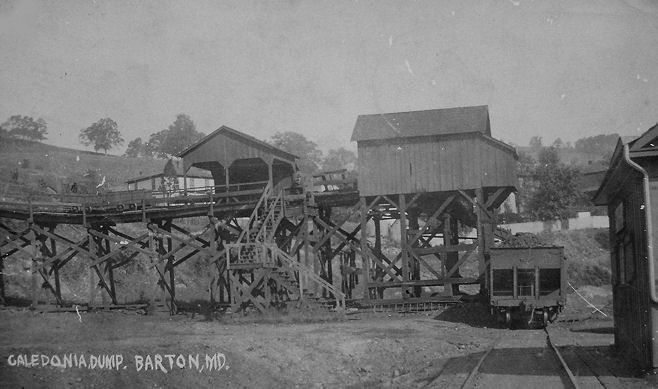

Caledonia Mine Tipple - Barton, MD

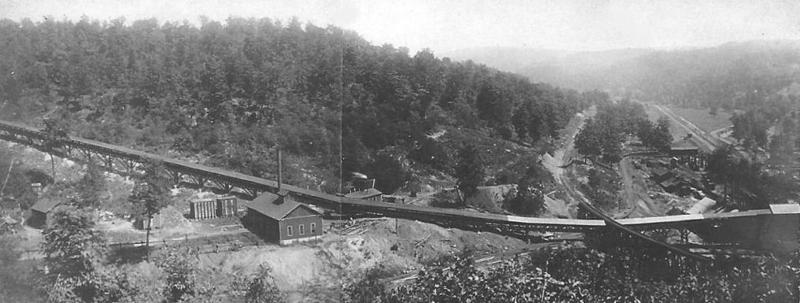

Coney Mine - Laconing, MD