PENNSYLVANIA MINES

Room-and-pillar mines have been active in Pennsylvania’s bituminous coalfields since the late-1700s. Bituminous coal was first commercially mined in Pennsylvania at "Coal Hill" (Mount Washington), just across the Monongahela River from the city of Pittsburgh. The coal was extracted from drift mines in the Pittsburgh coal seam, which outcrops along the hillside, and transported by canoe to the nearby military garrison. By 1830, the city of Pittsburgh consumed more than 400 tons per day of bituminous coal for domestic and light industrial use. Development of the anthracite coalfields in eastern Pennsylvania had progressed to the point where "hard coal" had captured the eastern markets. Consequently, bituminous coal production in western Pennsylvania grew principally with western population growth, expansion and development of rail and river transportation facilities to the west, and the emergence of the steel industry. Towards the last half of the nineteenth century, the demand for steel generated by the explosive growth of the railroad industry and ship building concerns, began to further impact bituminous coal production in western Pennsylvania. Until the maturation of modern longwall mining in the 1960s, Pennsylvania’s underground bituminous coal production came almost exclusively from room-and-pillar mines.

Settlers from Connecticut discovered the anthracite coal seams in the Wyoming Valley in 1762. The first recorded use of anthracite coal was in 1768. In 1775, mining of anthracite started in northeast Pennsylvania. The mine was located near Pittston. Wilkes-Barre saw the start of anthracite mining in 1776, with the mining occurring from outcrops along the banks of the Susquehanna River. In 1790, anthracite is discovered in the Schuylkill region of Pennsylvania and in 1792 anthracite is discovered in the Lehigh region of Pennsylvania.

In 1814, Cist & Robinson made their first shipment of coal to Philadelphia near Mauch Chunk. Two boatloads arrived at Philadelphia and were purchase by White & Hazard for $21 per ton and used at their wire mills at the fall of the Schuylkill, in the first successful effort to utilize anthracite in the iron industry. In 1815, White, Hazard and Hauto set about securing a lease on the Lehigh Coal Mine Company land near Mauch Chunk, for 10,000 acres for 20 years. In 1819, an open cut coal pit, which became known as "The Old Mine," in the Summit Hill area was started. This mine was located in the area of the "Mammoth Vein." This "mammoth" seam of coal was at one time the most important of all Anthracite deposits. In 1822 the Coal Company became incorporated under the name of Lehigh Coal & Navigation Company. As early as 1814, two prominent businessmen or entrepreneurs, Josiah White and Erskine Hazard, becoming involved with anthracite coal. These men were interested in promoting and marketing this new fuel. Because of them the building of the Lehigh Canal system came about. Also they were instrumental in building the first gravity railroad and the development of the vast coal lands between Tamaqua and Mauch Chunk.

During 1820, The Lehigh Coal and Navigation Company began mining and shipping coal. The price for a ton of coal at Philadelphia was $8.40. Shipment that year was 365 tons. In 1829, the Lehigh Canal from Mauch Chunk to Eastonwas opened. In 1837, Lehigh River navigation to White Haven was opened. In 1831 the Nesquehoning Railroad and plane was built. By 1849, the mine at Summit Hill had to be abandoned because of water. At that period of time, they didn't have the high volume water pumps and couldn't remove the water to keep the quarry operable. In view of some coal workings being soon worked out and also the large quarry being flooded, it was decided to drive a tunnel on a level with the bottom of the Panther Creek Valley into the Mammoth Vein on the south side of the valley. In 1845, plans for the No. 9 Mine were on the drawing board. Two attempts to drive the mine, in 1851 and 1853, were unsuccessful. In 1851 the Company set its goal to drive in around 800 yards to the Mammoth Vein. On January 14, 1852, a proposal was accepted from Daniel Bertsch to drive the No.9 tunnel, a distance of, "about seven hundred yards." In December of 1857, the Mammoth Vein was reached after driving a tunnel 2,283 feet. On March 31, 1858, a mining contract with Daniel Bertsch was ordered to be executed under Corporate Seal. The mine was finally closed in 1972. At that time it was the oldest continually operated coal mine in the U.S.

In 1842, William Henry, a native of Nazareth who had been operating a blast furnace in New Jersey, arrived with his son-in-law, Seldon T. Scranton. William Henry was a geologist and surveyor. He had previously visited the area and had discovered deposits of iron ore in the hills surrounding the Roaring Brook and Lackawanna River. Soon, Seldon's brother, George W. Scranton, arrived from Connecticut; the Slocum property was purchased, and funds were secured from a number of venture capitalists for the construction of the Lackawanna Furnace. By 1846, the Lackawanna Furnace and Rolling Mills Company was producing nails for market.

In 1847, the Scranton brothers invited their cousin, Joseph H. Scranton, who was a successful Georgia merchant, to invest in the growing industry. George secured a contract from the Erie Railroad to produce "T" rails for a line from Port Jervis to Binghamton. Conversion of the small iron-mill to a rail-producing factory was both expensive and risky. The project was completed on December 27, 1848. In the same year, a U.S. Post Office was established in the town then called "Scrantonia" named after the Scranton family. Also, during this time period the first wave of immigrants from England, Wales, Ireland, and Germany was beginning to settle in the region.

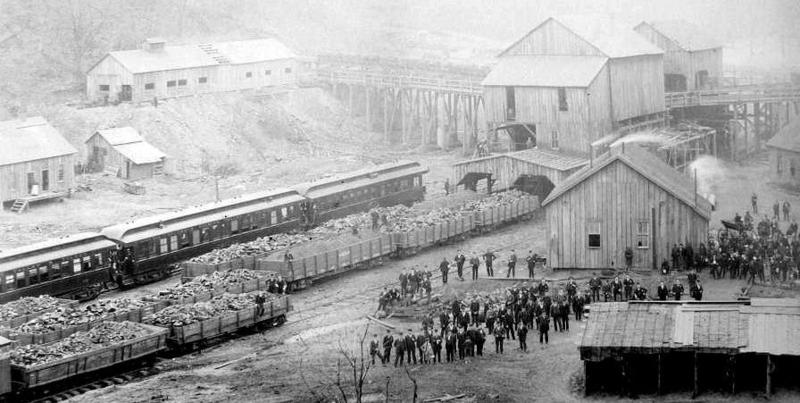

The Scrantons, realizing that there was money to be made from coal, began to concentrate on its mining and transportation in the 1850's. Their efforts led to the formation of the Delaware, Lackawanna & Western Railroad. The railroad company controlled a network of coal mines that had mined and shipped two million tons of coal by 1868.

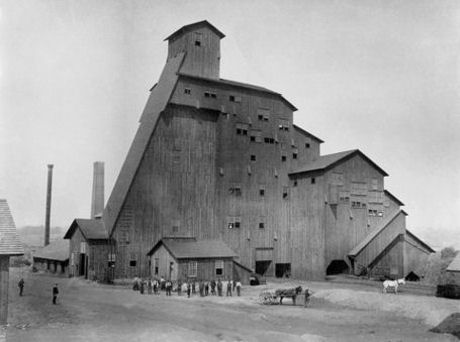

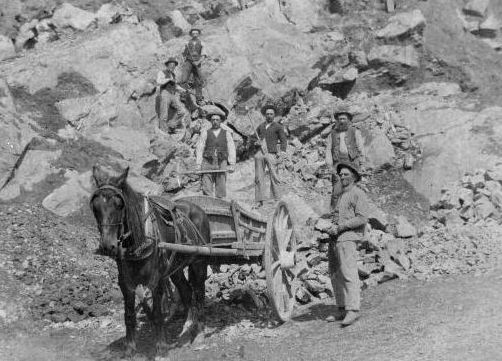

Graff Mining Co. - Blairsville, PA

Iron was an early and important mineral resource in Pennsylvania. The town of Cornwall was founded by Peter Grubb in 1737. Grubb, a Chester County stone mason, came to Lancaster County around 1734 in search of building materials. First building his house, and then a store, he discovered very high quality iron ore nearby and decided to mine it, acquiring 300 acres by 1737 and over 1,000 acres by 1739 when mining was initiated. He called it the Cornwall Iron Mines after his father's birthplace in Cornwall, England.

Ironmasters and workers commonly spoke of "mining" iron ore, but before 1850 it was something of a misnomer to describe this process as "mining." As Johann Schoepf, who traveled Pennsylvania, noted, "Any knowledge of mining is superfluous here, where there is neither shaft nor gallery to be driven, all work being at the surface, or in great, wide trenches or pits." Workers used pickaxes and pry bars to get the ore out of the ground. After digging the ore, they tried to remove as much waste, including clay and soil, as possible from the ore. One method was to "flat" the ore, or roll cast-iron, horse-drawn breakers over the ore. In the nineteenth century workers also often washed the ore to separate waste.

Ore in the rich, abundant Cornwall Banks in Lebanon County lay in two deposits. One deposit outcropped and was accessed easily. The top of the second deposit lay 150 feet underground; this deposit was not located until 1919. The first deposit proved to be the most important source of ore for area iron furnaces until the late nineteenth century.

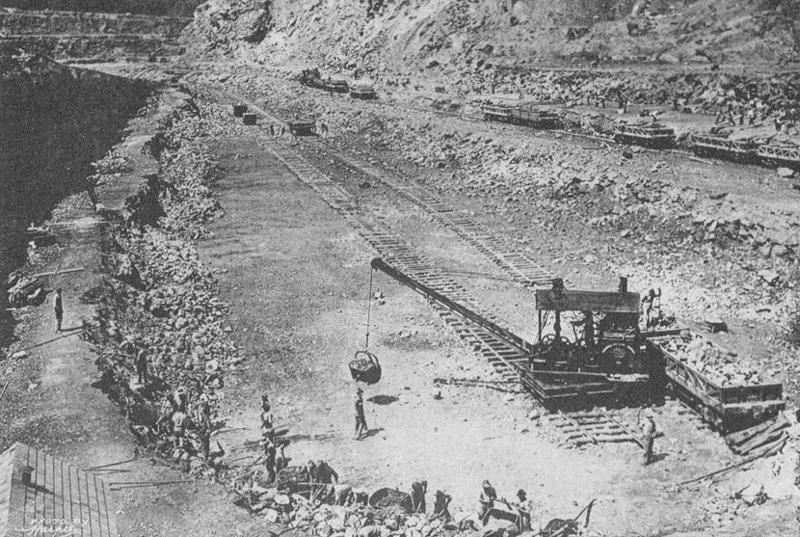

Until the mid-nineteenth century, the multiple owners relied upon the prevalent methods of using pick axes and pry bars to dig ore out of the ground. Miners opened pits or trenches around the deposit. By mid-century, owners increased production by improving the transportation of ore and greatly changing mining techniques. In 1858 bench mining replaced the earlier methods of mining. Miners extracted ore in benches or steps, each sixteen to twenty feet deep, creating one, growing open pit, instead of the earlier, small pits and trenches. During the 1870s steam shovels replaced the hand-loading of railroad cars.

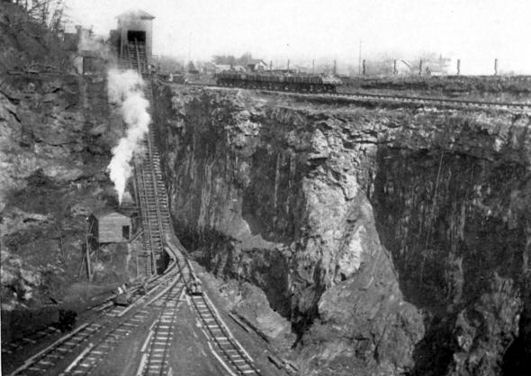

During the 1890s miners excavated 564,000 tons of ore each year on average. Owners continued to improve mining techniques, such as constructing an inclined hoist to haul coal out of the deepening pit. The Cornwall Iron Mines, also known as Cornwall Banks, turned out to be the largest United States' iron deposit east of Lake Superior, and were once the largest open-pit iron mine in the world.

During the 1890s miners excavated 564,000 tons of ore each year on average. Owners continued to improve mining techniques, such as constructing an inclined hoist to haul coal out of the deepening pit.

In 1926 mining began in the second ore deposit, and the Bethlehem Steel Corporation gained sole ownership of both deposits to supply ore to its steel mills. Mining continued until 1973 when Tropical Storm Agnes filled the mine with water. Engineers determined that the value of the remaining ore was not worth the cost of draining the mine. After 234 years of operation and total production of 106 million tons of ore, the Cornwall Banks closed down.

The Danville Iron Mines were a series of mines along Montour Ridge in the Clinton formation at Danville, exploiting the beds of the red Hematite deposits of Central Pennsylvania. Conveniently situated within the vast Anthracite region of NE Pennsylvania, the area also included sufficient local limestone to quarry for use in fluxing. Both "fossil" ore and "block" ore proved exploitable in the Danville area. Samples of ore from the Percell slope tested to levels as high as 38.7% FeO2. The combination of good ores, flux and technologically advanced metallurgical practices for the day, produced an iron of the highest quality.

The mines at Danville included Purcell Slope, Frosty slope, and Valley Slope on the N.W. side of Montour Ridge, Monkey Drift, Welsh Hill, and Water Level on the S.E. side, along with various privately owned and leased workings throughout the area. Descending at an incline of 30 to 40 degrees, these mines employed "long wall" mining, the earliest use of this "new" method of mining in Pennsylvania. Introduced by Welsh mining expert Daniel Edwards, first superintendent of mines for the Montour Iron co., who later, went on to become general manager of Kingston Coal Co. for the Montour Ironworks, this method was eventually employed in the majority of tunneling Coal mining operations throughout Pennsylvania.

In northern Chester County, the Upper French Creek valley had been worked by surface mines since 1717 for its easily obtained high quality iron deposits. The French Creek Mine tract, an 1845 surface extraction, extended its life to 1928 by the opening three deep shaft mines after 1860.

In 1845, Samuel Keim and Samuel Crosley, farmers living just above the Falls of French Creek, found, by the old open pit or surface method, that they had iron ore on their land. In 1847, they sold their discovery to Josiah Keim who, working with the E.& G. Brooke Iron Company (to whom he sold in 1848), tested for deeper iron by sinking a shaft. Not until the 1860s, however, did shaft mining begin in earnest. One thousand tons of iron ore and 45-50 tons of copper were extracted from the shaft in 1861..In 1866, the Brooke Iron Company merged with the Phoenix Iron Company of Phoenixville, and in due course, three shafts were sunk to depths of 200-360 feet with drifts running off the main shafts. The three shafts were called "The Elizabeth," "The Suzie," and "The Calamity" mines.

From these mines, which eventually reached a depth of 2250 feet, an estimated million tons of high quality iron ore were taken. By 1926, at roughly 1700-2000 feet, the ore became lean, and operations came to a slow halt. New explorations were tried in a four mile radius with little results. Had the explorations gone just a few miles further west, the later named 'Grace Mines' of Bethlehem Steel would have been found.

Iron Mine at Cornwall Banks - Lebanon Co., PA

Robesonia Cut and Hoist - Cornwall Banks, Lebanon Co., PA

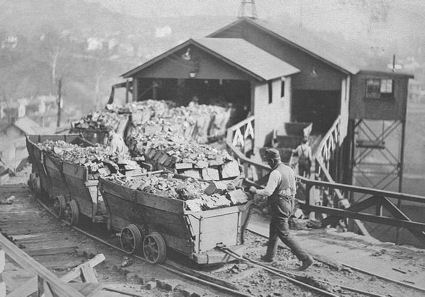

Open Pit Iron Miners - Cornwall Banks, PA

Robesonia Cut and Hoist - Cornwall Banks, Lebanon Co., PA

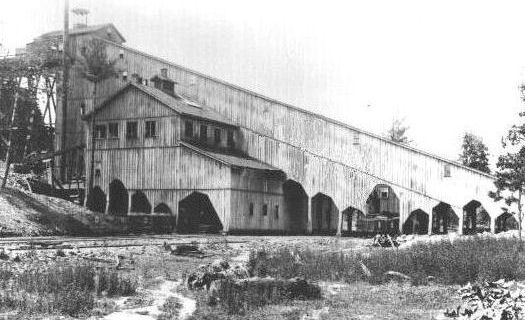

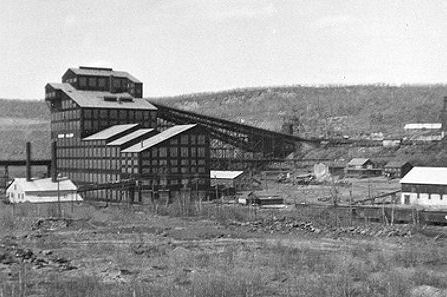

Lehigh & Wilkes-Barre Coal Co. Empire No.5 Breaker

Lansford No.6 Colliery - Lehigh Coal & Navigation Co.

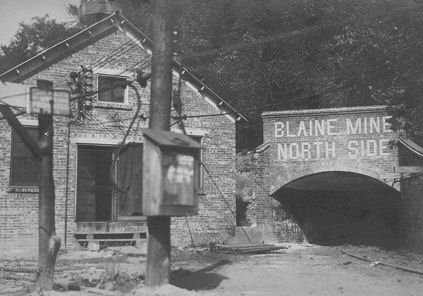

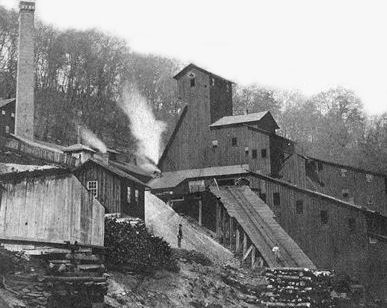

Blaine Mine - Elizabeth, Allegheny Co., PA

Blaine Mine - Elizabeth, Allegheny Co., PA

Blaine Mine - Elizabeth, Allegheny Co., PA

Among the first to realize the importance of anthracite coal were brothers John, William and Maurice Wurts. The brothers purchased land in what is today Carbondale and began mining coal. The Wurts had planned to ship the coal to Philadelphia but when coal mining began in the Lehigh and Schuylkill regions, those areas sufficiently supplied Philadelphia. The brothers then formed the Delaware and Hudson Canal Company in 1825 and opened the Delaware & Hudson Canal in 1828. The idea was to transport coal from the Carboandale area mines to Honesdale via a gravity railroad and from Honesdale to Roundout, New York, via canal. From Roundout, the coal was was to be transported down the Hudson River to New York City. With the success of the gravity railroad and canal system, additional gravity lines were extended from Carbondale throughout the valley.

The Delaware and Hudson Canal Company was the first million-dollar private enterprise in the United States, and it led to the first suspension aqueducts that were built by John A. Roebling of Brooklyn Bridge fame and later to the first successful operation of a railroad locomotive, the "Stourbridge Lion," in America, in 1829. The Delaware & Hudson was to develop into a major coal railway company.

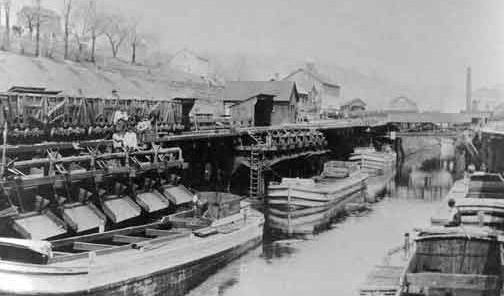

Delaware & Hudson Canal - Honesdale coal bunkers

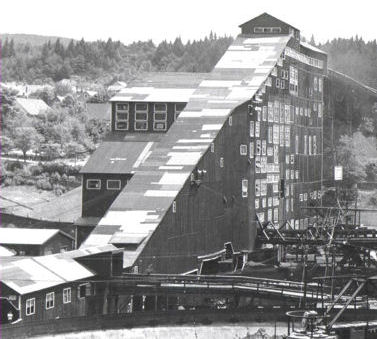

Glen Lyon Breaker - Glen Lyon, PA

Seneca Duryea Breaker

Woodward Mine - Kingston, PA

Woodward Breaker - Kingston, PA

Hudson Coal Co. Powderly Anthracite Mine - Carbondale, PA

Hudson Coal Co. - Carbondale, PA

Sibley Colliery 1886

Delaware, Lackawanna & Western Railway Co. Avondale Breaker

Delaware, Lackawanna & Western Railway Co.

Over 10 billion tons of bituminous coal have been mined in 21 Pennsylvania counties during the past 200 years of mining. This is about one fourth of all coal mined in the United States. The counties containing coal mines are: Greene, Somerset, Armstrong, Indiana, Clearfield, Washington, Cambria, Jefferson, Westmoreland, Clarion, Elk, Fayette, Lycoming, Butler, Lawrence, Centre, Beaver, Blair, Allegheny, Venango and Mercer (ranked in order of production). About 40 different beds (layers) of coal are/were mined in Pennsylvania. About 75 percent of Pennsylvania's coal is mined from five different beds: the Pittsburgh Coal Seam, the Upper and Lower Freeport Coal Seam and the Upper and Lower Kittanning Coal Seam.

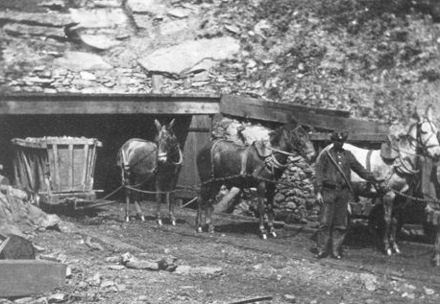

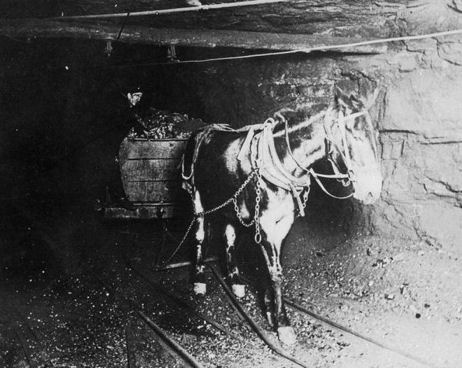

There are several methods of mining, the room and pillar method, with or without retreat mining, and the long wall method. Until the maturation of modern longwall mining in the 1960s, Pennsylvania’s underground bituminous coal production came almost exclusively from room-and-pillar mines. Early Room and pillar mining did not include retreat mining, because they relied on manual labor to cut the coal at the front and the coal was then hauled from the mine by horse or donkey and wagon. Although coal recovery is relatively low using the room-and-pillar method, normally ranging between 35 and 70 percent, this method has been active in Pennsylvania's Bituminous coal fields since the late 1700's.

Pittsburgh Coal Co. Montour No.4 mine - Pittsburgh, PA, 1942

Powderly Mine - Carbondale, PA

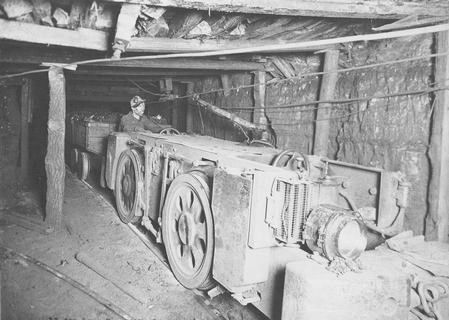

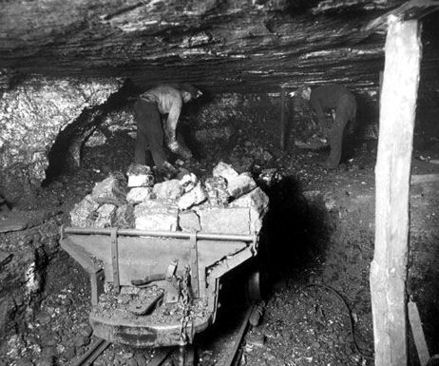

Hand-powered mechanical coal loader - PA

Loaded coal cars leaving a mine - PA

Hand loading coal

Philadelphia & Reading Coal & Iron Co.

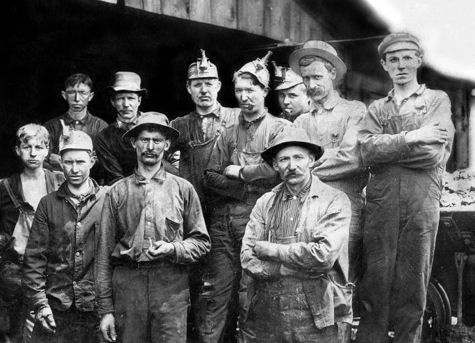

Miners - Scranton PA

Miner and mule underground

Loading a coal car - Scranton, PA

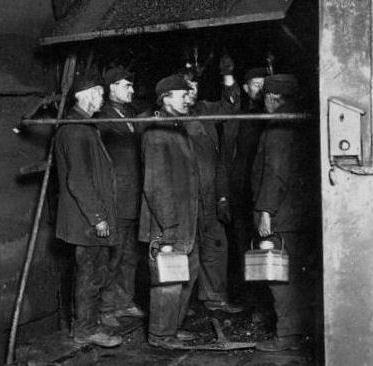

Descending a mine slope - PA

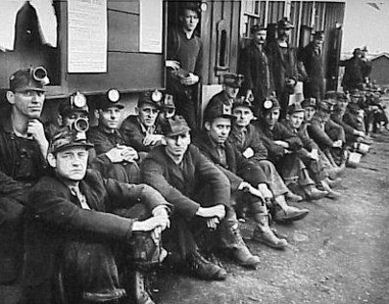

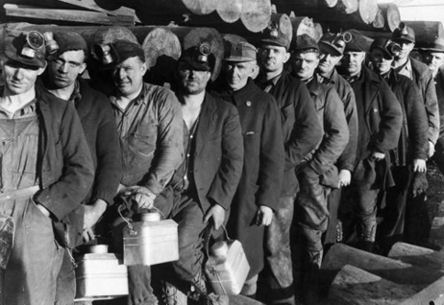

Pennsylvania coal miners

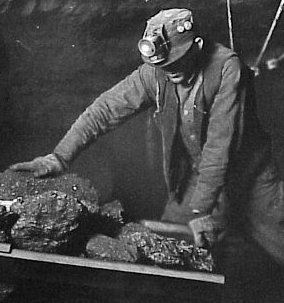

Hand loading iron ore - Cornwall Banks, Cornwall, PA

Loading iron ore - Cornwall Banks, Cornwall, PA

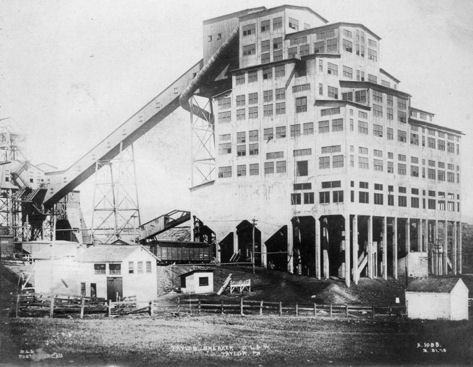

DL&W Taylor Breaker - Taylor, PA

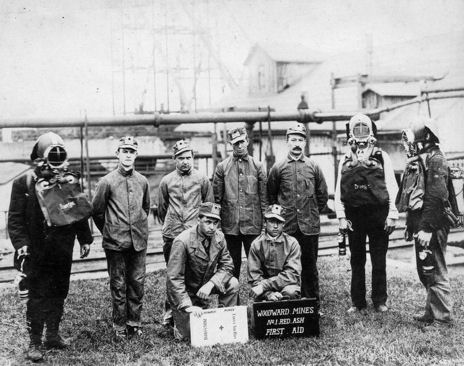

DL&W Woodward Mine First-Aid & Rescue Team 1910

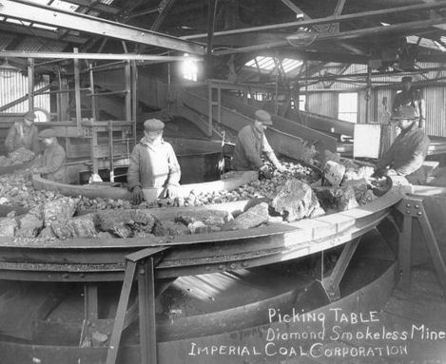

DL&W Diamond Coal Mine - Scranton, PA

DL&W Diamond Coal Mine - Scranton, PA

DL&W Diamond Coal Mine - Scranton, PA

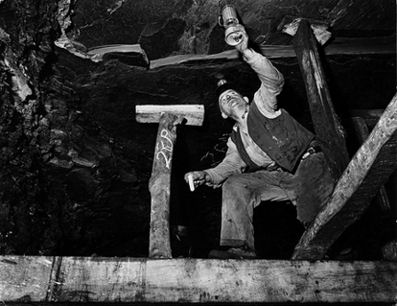

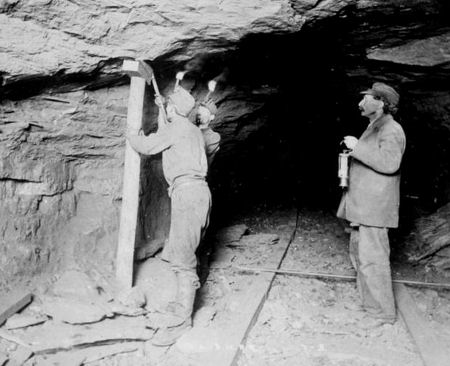

Hand Drilling in the DL&W Diamond Coal Mine - Scranton, PA

DL&W Diamond Coal Mine - Scranton, PA

DL&W Diamond Coal Mine - Scranton, PA

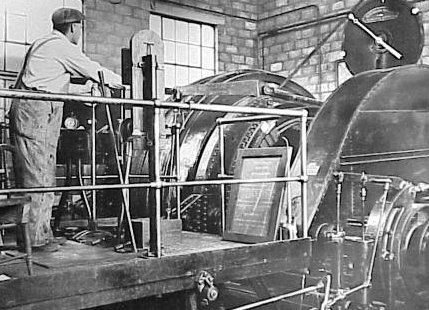

Hoistman - Philadelphia & Reading Coal & Iron Co

Mechanical Coal Loader - Philadelphia & Reading Coal & Iron Co.

Sibley Colliery 1886

Pittsburgh Coal Co. Powell's Run Mines

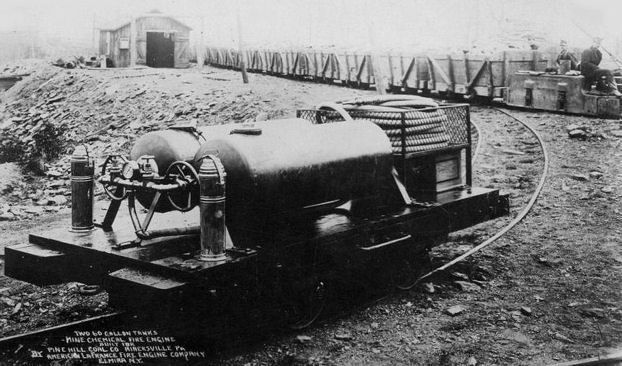

Pine Hill Coal Co.Chemical Fire Engine - Minersville PA

Pennsylvania coal miners ready to descend in the cage

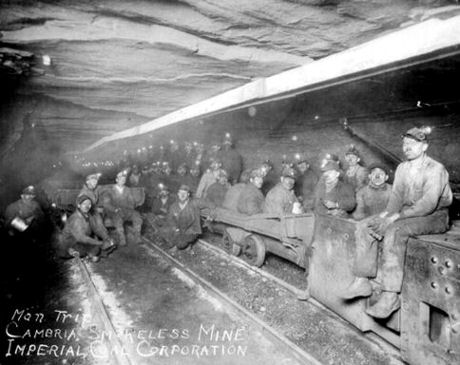

Loading a coal car - Imperial Coal Corp. Diamond Smokeless Mine

Imperial Coal Corp. Cardiff Mine Tipple

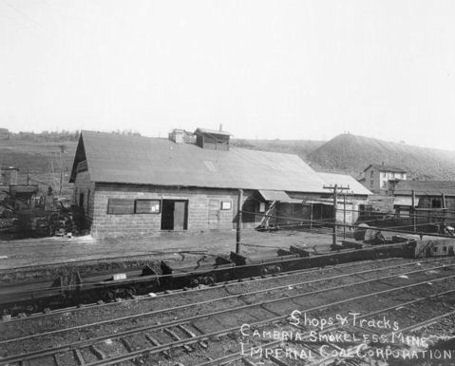

Imperial Coal Corp. Cambria Smokeless Mine

Cambria Smokeless Coal Co.Tipple

Imperial Coal Corp. Diamond Smoleless Mine Tipple

Open Pit - Middle Hill, Cornwall, PA

Pyne Breaker - PA