Mines of Wales

Silver Miners - Cardiganshire, Wales

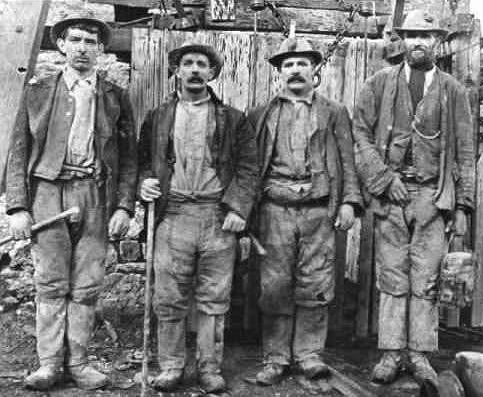

Coal Miners- Ebbw Vale, Wales

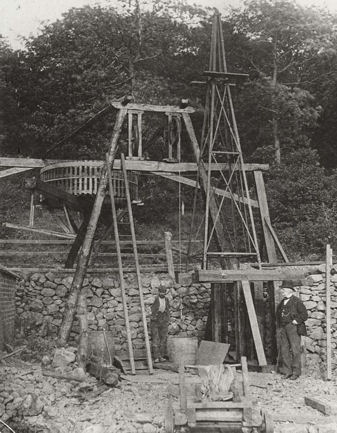

Bodfari Iron Mine - Wales

Roman Deep Mine - Pumsaint, Carmarthenshire

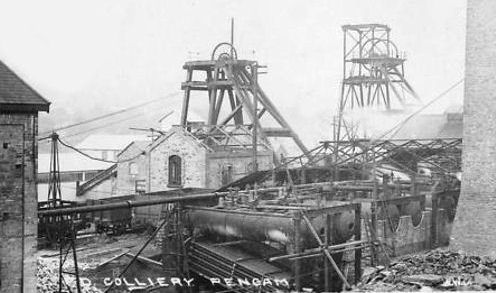

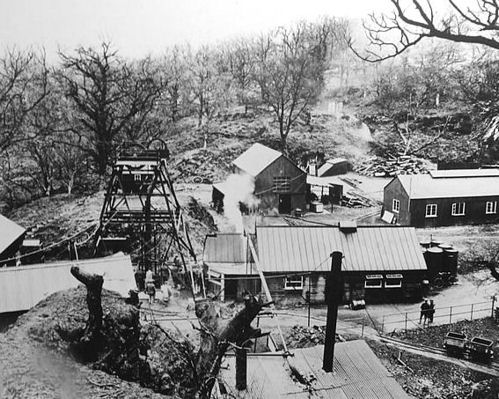

Pengam PD Colliery - Rhymney, Wales

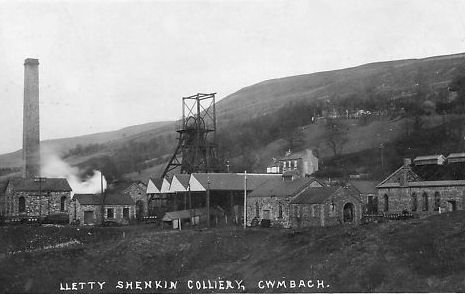

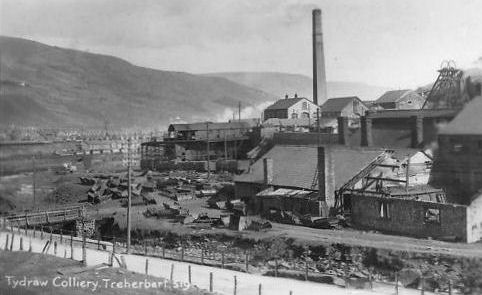

Tydraw Colliery - Treherbert, Wales

Miners - Rhonda Valley, Wales

Miners - Rhonda Valley, Wales

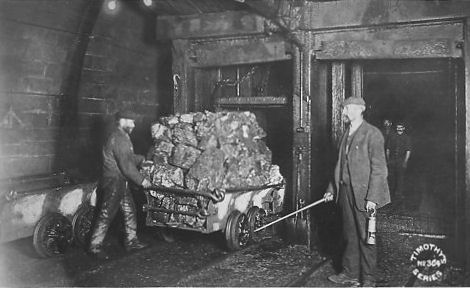

Loaded Coal Car - Rhonda Valley, Wales

There had been small-scale mining in Wales in the pre-Roman British Iron Age, but it would be undertaken on an industrial scale under the Romans, who completed their conquest of Wales in AD 78. Substantial quantities of gold, copper, and lead were extracted, along with lesser amounts of zinc and silver. Mining would continue until the process was no longer practical or profitable, at which time the mine would be abandoned. The extensive excavations of the Roman operations at Dolaucothi provide a picture of the high level of Roman technology and the expertise of Roman engineering in the ancient era.

There is evidence of mining in the Blaenavon area going back to the 14th century, and there is evidence of mine workings at Mostyn as far back as 1261, but it is believed to have been practised even as early as Roman times. The coal mining industry burgeoned throughout the Industrial Revolution and into the 19th century, when shafts were sunk to complement the open-cast mining and drift mining already exploiting the ample and obvious coal resources.

During the first half of the nineteenth century mining was often at the centre of working-class discontent in Wales, and a number of uprisings such as the Merthyr Rising in 1831 against employers were a characteristic of the Industrial Revolution in Wales. The Chartist movement and the 1839 Newport Rising showed the growing concerns and awareness of the work force of their value to the nation. Although the Factory Acts of the 1830s and resultant Mines Act of 1842 was meant to prevent women and boys under 10 years of age from working underground, it is believed to have been widely ignored. To replace female and child labour the pit pony was more widely introduced. Much later, in the middle of the 20th century, mining was still a hazardous enterprise, resulting in many accidents and long term ill-health with many of Blaenavon's older citizens still suffering from silicosis and other mining related diseases.

Incorporating the existing Coity colliery and Kearsley's pit (sunk in 1860), the Big Pit opened in 1880, so called because it was the first shaft in Wales large enough to allow two tramways. At the height of coal production, there were over 160 drift mines and over 30 shafts working the nine seams in the Blaenavon locality. Big Pit alone employed some 1,300 men digging a quarter of a million tons of coal a year. Large amounts of coal were needed to supply the local ironworks, as it took 3 tons of coal to produce a ton of iron. Blaenavon 'steam' coal was of high quality and it was exported globally. Burning hotly while leaving minimum ash, it was ideal to power the steam engines that drove steamships, Dreadnoughts of the Royal Navy and steam locomotive railways across the world.

However both economics and politics after World War I with its resultant general strike, the 1930s Depression and later Nationalisation and the miners' strike of 1984-1985 took their toll and all the smaller pits were either abandoned or swallowed into Big Pit's encroaching search for new seams. Finally in February 1980 the coal ran out and even Big Pit, then the oldest mine in Wales, had to close. There are still nine headframes remaining in Wales, including Big Pit (the metal frame erected in 1921 during the Miners' Strike of that year, to replace a wooden structure).

The earliest known Welsh gold mine was the Dolaucothi Gold Mines near Pumsaint in Carmarthenshire, which was initiated by the Romans in or about 74 AD, and closed in 1938 and was donated to the National Trust in 1941. A hoard of gold objects was found near the village of Pumsaint close to the mines in the 18th century and is now in the British Museum.

However, Dolaucothi is best known for its exploitation on a large scale during the Roman period, from about 75 AD on to 300 AD at least. Hydraulic mining methods preceded opencast and then deep mining at the site. The many opencast workings were produced by hushing and fire-setting during the Roman period in Roman Wales. The workings were initially under military control with a small Roman fort under the present village of Pumsaint and the workings have yielded large amounts of late Roman pottery (77 AD to 300 AD plus) from the reservoir known as "Melin-y-milwyr" or soldiers mill.

The Gwynfynydd Gold Mine in Dolgellau closed in the late 1990s. Gwynfynydd was discovered in 1860. It was active until 1998 and has produced 45,000+ troy ounces of Welsh gold since 1884. Queen Elizabeth was presented with a kilogram ingot of Welsh gold on her 60th birthday (April 1986) from this mine. In the 1990's the mine was open to the public and provided guided tours which included the opportunity to pan for gold. The mine closed because of health and safety issues and because of changing pollution control legislation which would have made the owners liable for the quality of the mine discharge into the River Mawddach had the mine remained open.

Another gold mine lies nearby, the Clogau mine. After producing copper and a little lead for quite a number of years, the mine developed into gold production in the 1862 gold rush and continued as a major operator until 1911 during which time 165,031 tons of gold ore were mined resulting in 78,507 troy ounces (2,442 kg) of gold. It worked the St David's lode of Clogau mountain alongside the co-owned Vigra Mine. Since 1911, the mine has been re-opened several times for smaller scale operations. It last closed in 1998.

Gwynfynydd Gold Mine Waterwheel

Dolaucothi Gold Mines - Carmarthenshire

Dolaucothi Gold Mines - Carmarthenshire

Parys Mountain - in the Welsh language Mynydd Parys - is located south of the town of Amlwch in north east Anglesey, Wales. It is the site of a large copper mine that was extensively exploited in the late 18th century. The mountain was mined for copper ore in the early Bronze Age, as shown by sub-surface debris nearly 4,000 years old revealed during excavations in 2002. Since then access has been regained to the sealed underground workings of the Parys mine revealing further evidence for this ancient mining. Parys Mountain is thus one of the few sites in Britain where there is evidence for the prehistoric beginnings of the British metal mining industry.

The 18th century miners recognized that they were following the work of much earlier miners, an observation that was then linked to the discovery locally of copper ingots bearing Roman inscriptions. In 1764 Charles Roe, of Macclesfield, was granted a 21-year lease by the Bayly family to work the mountain for copper. Rowland Pugh, a local miner, discovered the "Great Lode" on 2 March 1768 and was rewarded with a bottle of whisky and a rent-free house for his lifetime.

Although the ore here was of low quality, this was more than compensated for by the fact that it occurred in two large masses close to the surface. Initially ore was worked on the surface from shallow shafts, next by open-pit mining and finally underground from adits or from shafts. The ore was broken into small lumps by hand, the best ore being shipped to Lancashire or to the Lower Swansea Valley in South Wales through the port of Swansea for smelting. Copper was concentrated and extracted from the remainder using kilns and furnaces on site. It was also discovered that purer metal could be obtained efficiently, although in small amounts, by its precipitation from drainage water with scrap iron in purpose-built ponds. Associated with the mines, important chemical industries were established on the Mountain based on by-products such as ochre pigments, sulphur, vitriol and alum. The processes were described by the German writer and translator, Augustin Gottfried Ludwig Lentin (1764–1823) who visited Parys Mountain in the 1790s and published his findings in Briefe über die Insel Anglesea : vorzüglich über das dasige Kupfer-Bergwerk und die dazu gehörigen Schmelzwerke und Fabriken (Leipzig : Crusius, 1800).

Parys Mountain dominated the world's copper market during the 1780s, when the mine was the largest in Europe. Its rise severely damaged the mining industry in Cornwall. The copper from the mine was used to sheath the British Admiralty's wooden ships of war, to prevent the growth of seaweed and barnacles and to protect the wood from attack by shipworms. This increased the speed and maneuvarability of the vessels, and enabled them to remain at sea for longer as there was less need to return to port for maintenance.

In response to a national shortage of small currency, the Parys Mine Company produced its own coinage between 1787 and 1793. The Parys Penny, also known as the Anglesey Penny, was used by the mine to pay workers, and also by the populace at large. It is thought that around ten million pennies and half pennies were minted.